About Me

I’m a Data Scientist and Mechanical Engineer, currently pursuing a Master’s degree in Advanced Precision Engineering at Hochschule Furtwangen in Germany.

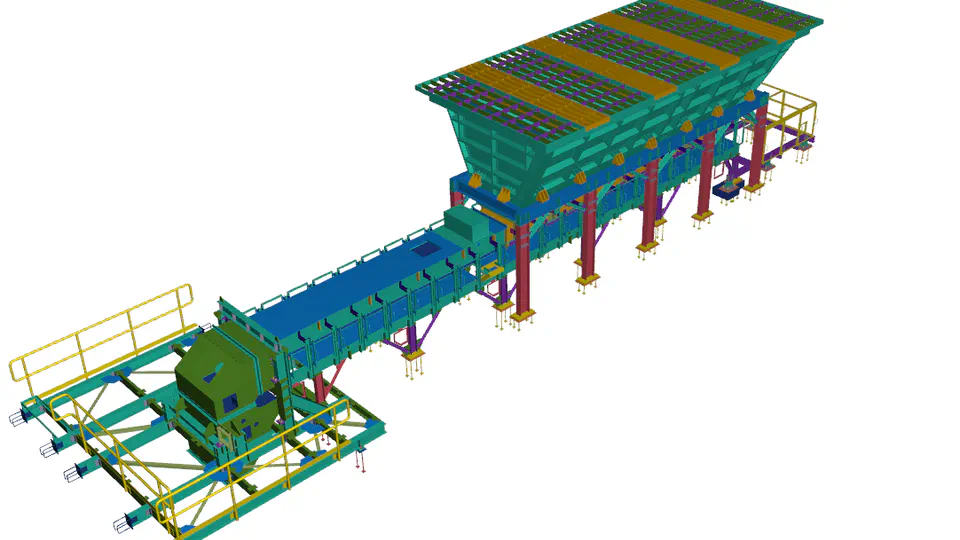

Alongside my academic journey, I work at Bosch Rexroth, where I design and implement Docker-based ETL pipelines and real-time monitoring systems for hydraulic systems. My role focuses on connecting physical systems with intelligent software solutions, contributing to the future of industrial automation.

My story begins in Peru, where I graduated top of my class in Mechanical Engineering from the Universidad Nacional de San Agustín de Arequipa (UNSA). My academic excellence earned me the prestigious Beca Presidente del Perú, a national scholarship awarded to students with the highest performance in the country.

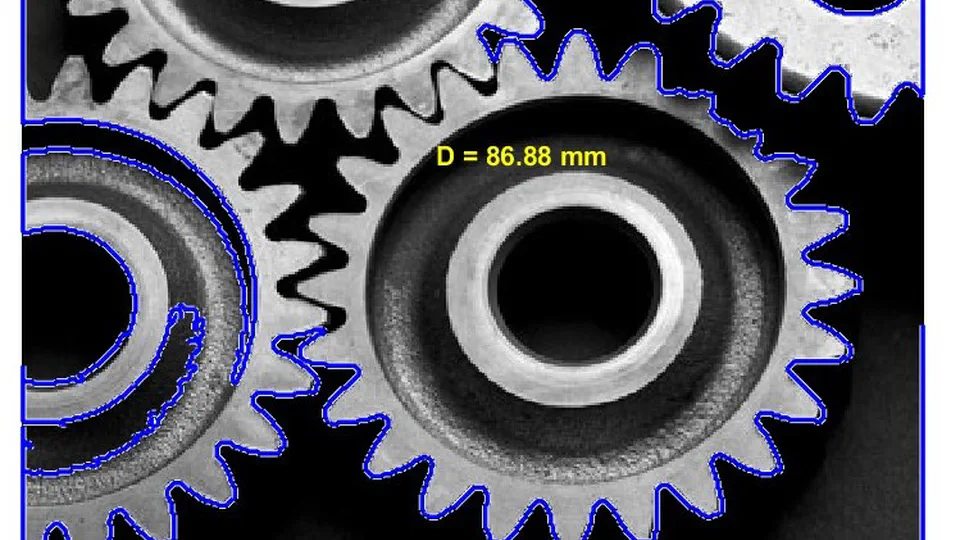

Later, I was selected as one of 100 finalists out of 16,000 applicants to join Freeport-McMoRan, where I applied Machine Learning for predictive maintenance (Remaining Useful Life) across global mining operations—combining data science with high-stakes, real-world engineering.

My work bridges engineering and intelligent systems, with a strong emphasis on practical implementation and scalable solutions. I specialize in:

Machine Learning & Time-Series Modeling

Predictive maintenance, anomaly detection, and signal analysis using Python, PyTorch, and scikit-learn.Dockerized ETL Pipelines & Cloud Integration

Modular, real-time data pipelines built with Dagster, orchestrated in Docker, and deployed on cloud platforms like Azure.Industrial Communication & Monitoring (OPC UA)

Design and implementation of robust monitoring architectures using OPC UA for data acquisition in manufacturing systems.Technology Stack

Python, PostgreSQL, Power BI/Grafana, Git, Azure ML — integrated into reliable and reproducible workflows.

I aim to pursue a Ph.D. in Robotics, Control Systems, or Industrial AI, developing impactful technologies that bridge data and physical systems.

- Smart Systems for Industrial Engineering and Robotics

- Technical Software Architecture & Data Automation for Industry 4.0

- Fusion of Data Science with Physical Modeling

B.Sc. in Mechanical Engineering

Universidad Nacional de San Agustin de Arequipa